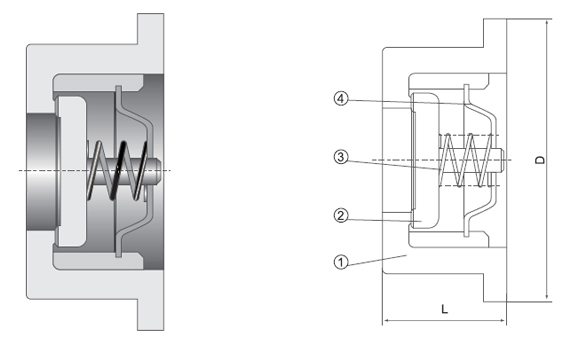

Cast steel check valve

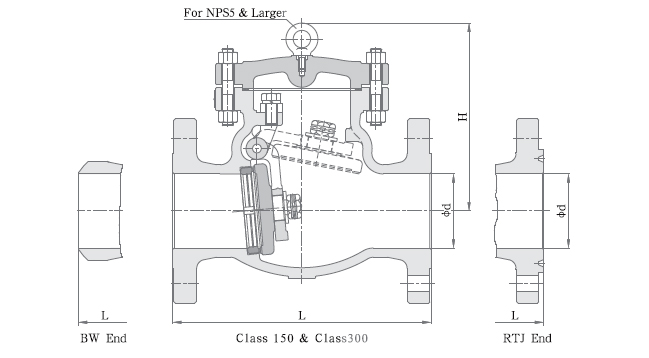

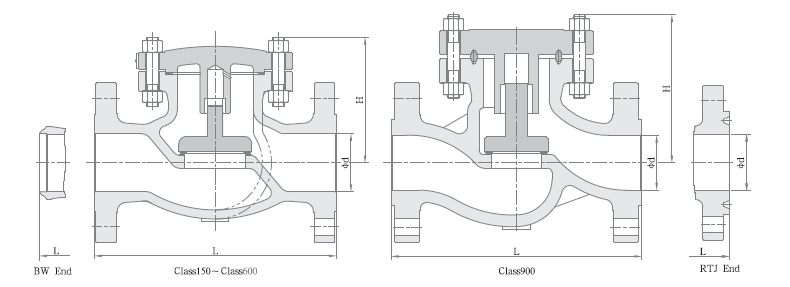

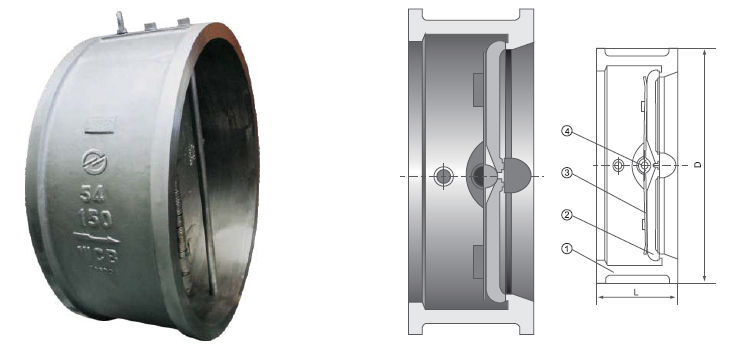

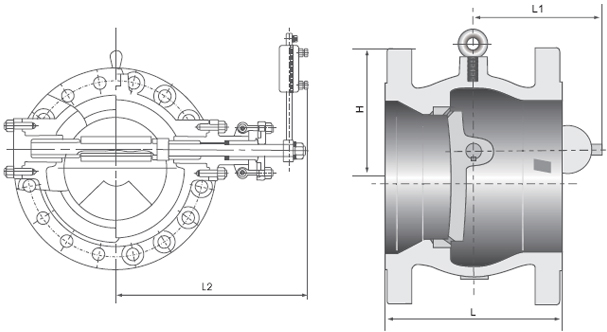

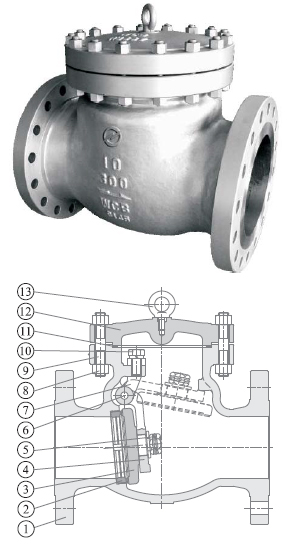

Bolted Bonnet, Swing and lift disc; Metallic seating surfaces.

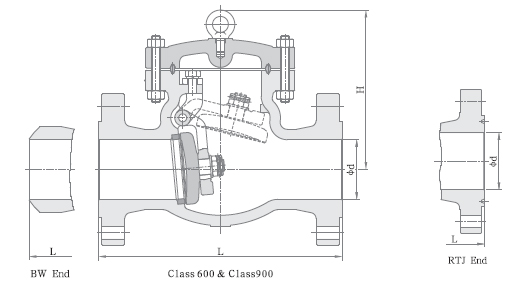

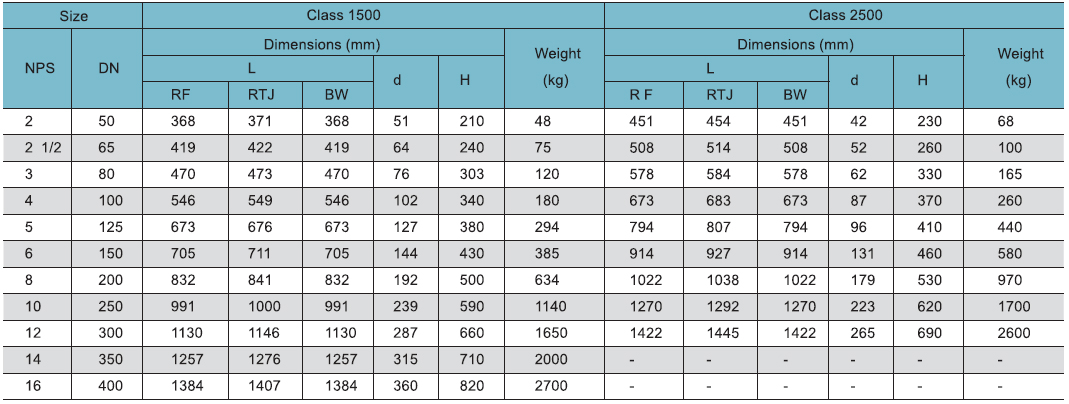

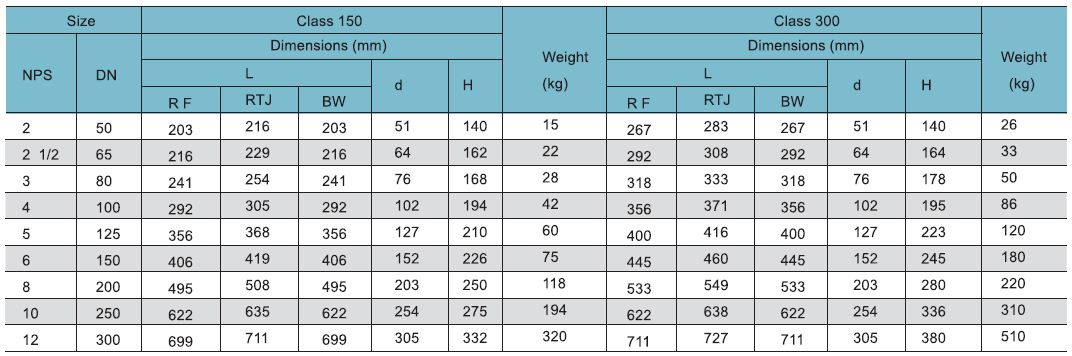

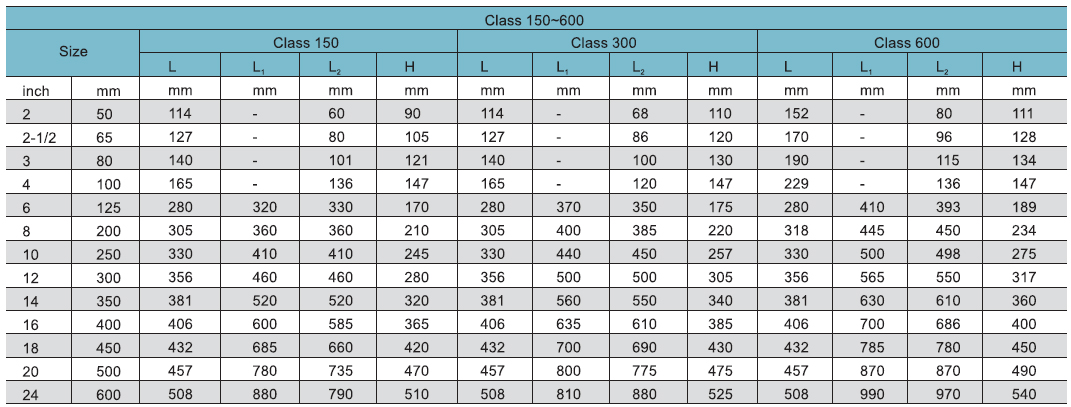

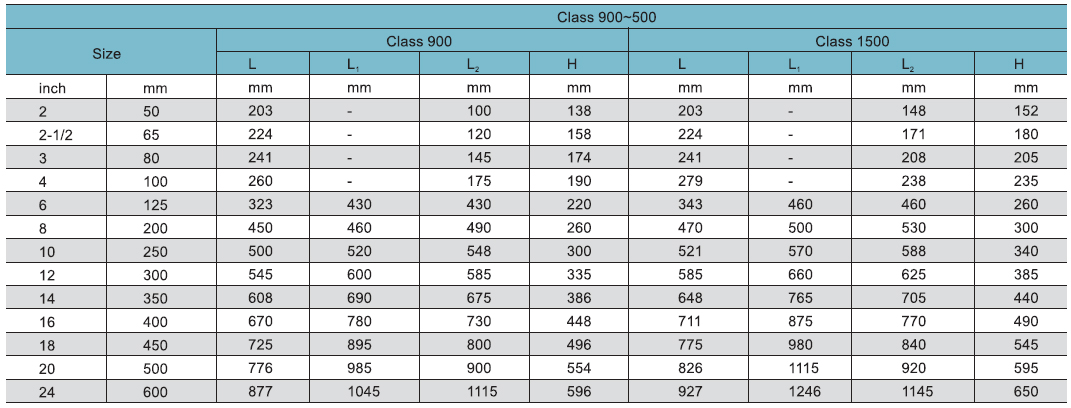

The body and bonnet of Class150 ~Class900 check valves are usually with studs and nuts. And the body and bonnet of Class1500 ~ Class2500 check valves are usually of pressurized seal design.

Stainless steel + flexible graphite wounded gasket is used for Class150 and Class300 check valve; Stainless steel + flexible graphite wounded gasket is used for Class600 check valve, and joint gasket is also optional for Class6Q0 check valve; Ring joint gasket is used for Class900 check valve; Pressurized seal design is used for Class 1500 ~ Class2500 check valves.

For carbon steel check valve, the seat is usually forged steel. The sealing surface of the seat is spray welded with hard alloy specified by the customer. Renewable threaded seat is used for NPSQ10 check valves, and welded on seat can be also optional if being requested by the customer. Welded on seat is used for NPSQ12 carbon steel gate valves. For stainless steel check valve, integral seat is usually adopted, or to weld hard alloy directly integrally. Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

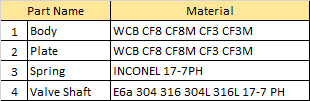

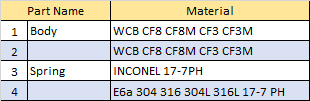

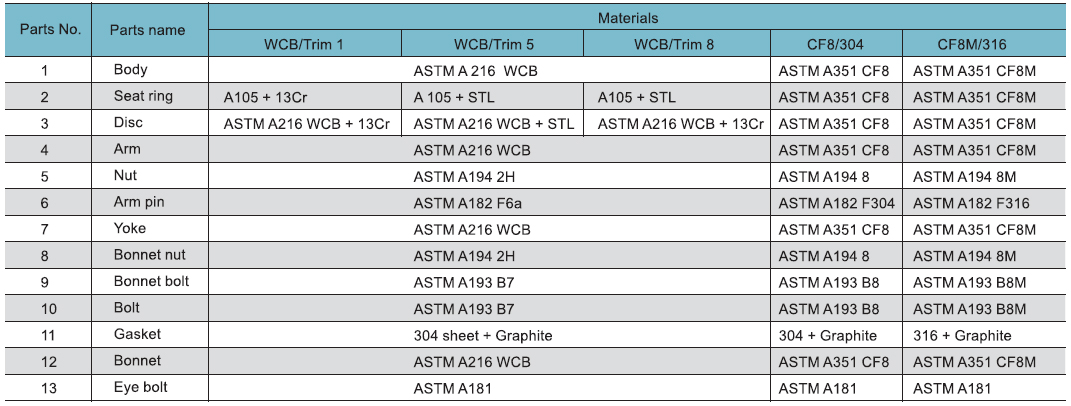

Note: The chart above only lists out some common composition of steel check valve parts. We may provide other different parts material composition according to the customer ‘s request or the actual valve working condition.