Centrifuges and bottom valves

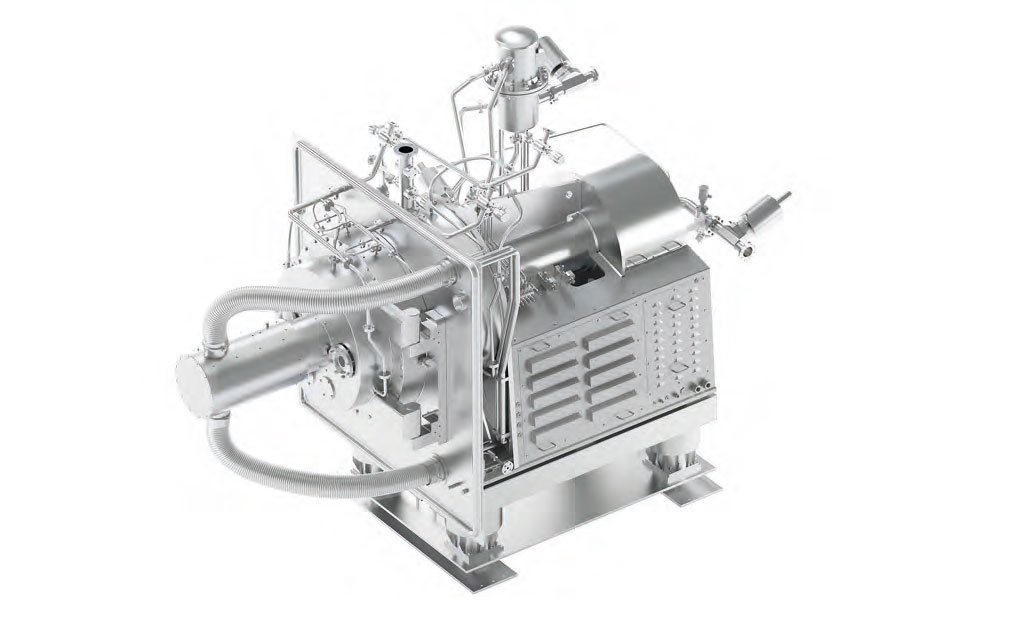

Separation of suspensions and emulsions is often done using centrifuges. With the FIMA centrifuge dryer, the additional process of drying of the substance takes place at the same time in a closed system. The dead space-free bottom valves from FIMA are also special. This type of valve is specifically designed to close with the piston flush with the inner wall of the tank.

Centrifuges are used in a variety of areas, for instance, for separation of suspensions, emulsions, and gas mixtures. The uniform circular movements and the associated centrifugal force allows the substances to be separated from one another.

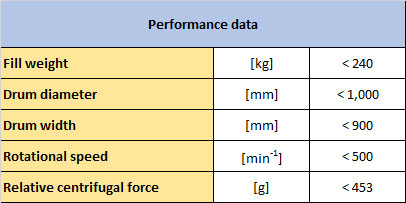

FIMA centrifugal dryers separate components in solid–liquid suspensions and dry them in a single machine. The specific machine construction guarantees a hermetically sealed product chamber that can be inerted and sterilized. Thus, foreign particles in the product are avoided and simple, gentle product handling is ensured.

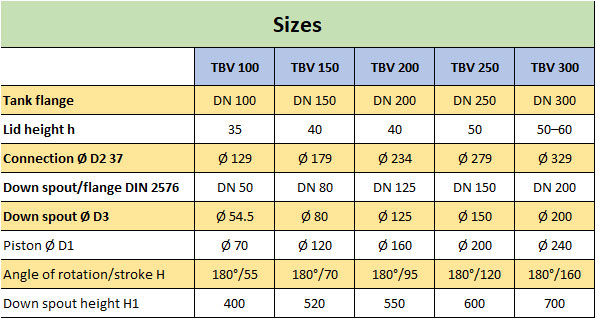

The dead space-free bottom valves from FIMA enable easy discharge, dosing, and dead space-free sealing. The valve is designed in such a way that via the lipstick-like rotating and lifting movement of the piston, the discharge pipe cross section is opened up or sealed off. In closed state, the piston is flush with the tank inner wall.

This specific type of valve is used in the biochemical, pharmaceutical, and food industries as well as in the fine chemical industry. FIMA bottom valves meet the high technical demands of these industries. They are suitable for powdered, granular bulk materials as well as for liquids, suspensions, and free-flowing paste products.