F2 Series

Hermetically encapsulated blowers and compressors

Our HETICO® (Hermetically Tight Compressor) and MACOUCO® (Magnetic Coupling Compressor) machines are specially built to guarantee an absolute seal. No gases can enter the process from the outside and no gases can escape from the process.

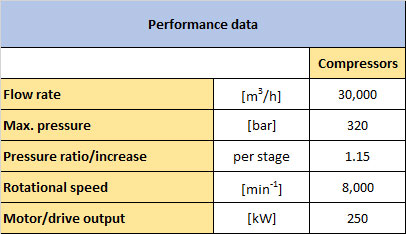

HETICO®

In the FIMA HETICO®, the impeller and the drive are both encapsulated in a single casing. In this way, dynamically loaded seals between the process area and the surroundings are avoided. The special gas-tight design of the HETICO® ensures that in applications with positive pressure, no process gas escapes into the outside atmos- phere. Conversely, it prevents outside air from entering the process in vacuum applications.

The explosion-proof design makes it suitable for use in explosive atmospheres and for conveyance of explosive media. It satisfies the requirements of

Pressure Equipment Directive PED 2014/68/EU. The HETICO® is already being successfully deployed not just in laminate manufacturing, in thermal power stations, and in thermal exhaust gas treatment plants but also in satellite test beds. In a number of processes, it is used as a recirculation blower.

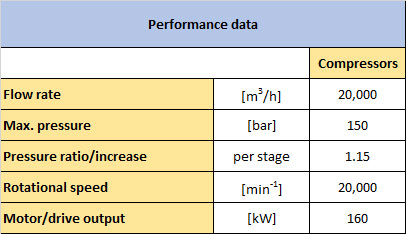

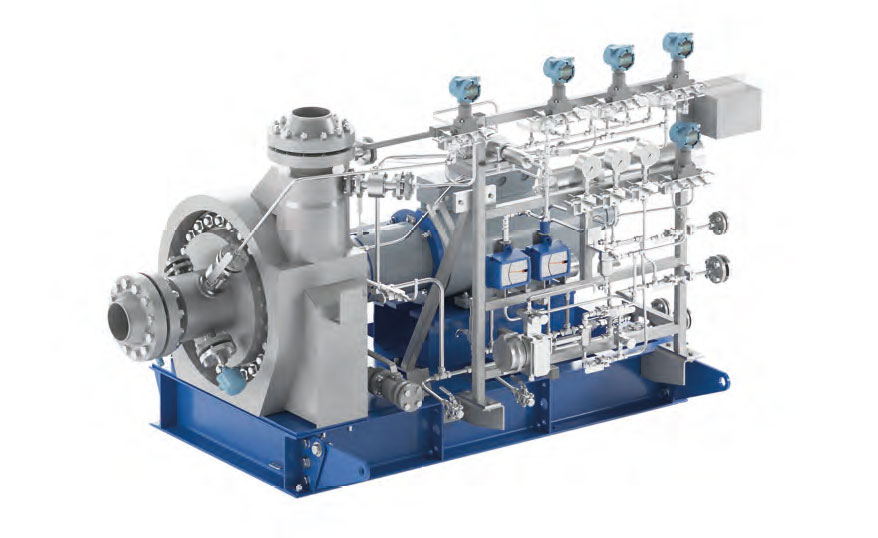

MACOUCO®

Due to the basic design of the magnetic coupling, the FIMA MACOUCO® is more environmentally compatible than conventional machine types are. In the MACOUCO®, the magnetic coupling and the bearing unit are flanged directly to the compressor housing, which is separated from the bearing unit through a gas-tight thermal insulation barrier. The hermetically sealed construction prevents dangerous gases from escaping into the environment. Without the need for dynamic seals, it is possible to obtain leak rates of less than 10-6 mbar*L/s with the FIMA MACOUCO®.

Areas in which our MACOUCO® is used include polyolefin plants (catalloy, spherilene process), chlorine gas, regeneration, recovery, and recycling processes, and sterilization plants for surgical and medical instruments.