Metal To Metal Sealed Ball Valve

BALL VALVE

Metal To Metal Sealed Ball Valve

Brief Description

The seat material of general purpose ball valve employs generally nonmetal material, such as PTFE. Limited by the seat material, the general purpose ball valve can not be used in case of high temperature application, and application medium with solid articles, and ash dregs neither. So, the application scope of general purpose ball valve is restricted partially. Taking this into consideration, SUNGO company has developed successfully after years of hard study full range of metal to metal sealed ball valve, including floating ball valve and trunnion ball valve,which have found extensive applications in such industries as petroleum, chemistry, power, metallurgy, and light industry.

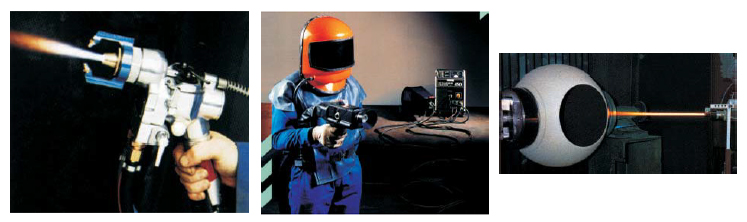

Ultro-sonic spray coating for ball and seat

Design features of metal to metal sealed ball valve

Except for such features as wrong operation prevention, stem blow-out proof, mounting pad provited, the metal to metal sealed ball valves made by SUNGO posses the following unique features.

Advanced Hardening Technology Employed For Ball And Seat

Metal to metal sealed design has been employed perfectly for the ball and seat, which has also adopted the advanced hardening technologies, such as ultro-sonic spray coating, nickel base spray welding, surface specially hardening, stellite spray welding, ceramic material with high strength and hardness, and so on. Surface hardness of the ball and seat may generally reach more than HRC60, Maximun is up to HRC74,and application temperature of the material may be up to 540 1 Maximun is 980 .Combining strength of the material gets to more than 10000 PSI. Besides, the surface materials posses also very good resistance properties of friction and impact. Metal to metal sealed ball valves made by SUNGO are suitable for use in most criticle working conditions.

Valve Stuck Under High Temperature Prevented

In the case of high temperature working condition, the valve seat and ball would easily get stuck due to heat expansion, and the valve could not be open. Metal to metal sealed ball valves made by SUNGO employ the patented design of bevelling spring loading, which would absorb the heat expansion of parts caused by the bevelling spring. So, it is ensured that the valve would not get stuck and be open and close easily in the case of high temperature condition.

Excellent Tightness Function

A unique technique has been employed for the ball grinding, which makes the ball surface reach extreme round and smooth by rotating the ball and grinding apparatus at different directions in space. The tightness function of the valve meets completely and exceeds the standard requirement.

An Entire Fire Safe structure

The metal to metal sealed structure has been adopted for the valve sealing surface design. Packing is so designed with graphite, and gasket is so designed with stainless steel, plus graphite that the valve can assure reliable tightness even if underfire condition.

Natural anti-atatic structure

Metal to metal sealed ball valve with its body seat, ball, other metal parts, and so forth, closely contact with each other, having naturally formed a static electricity passage. In this respect, there is no need to provide special anti-static device.

Double-block And Bleed Function

SUNGO’s metal to metal sealed trunnion ball valve is in general of the front ball sealing structure. Actually, two seats of the metal to metal sealed trunnion ball valve can both cut off separately the medium at inlet and outlet to realize double-block function. When the valve is closed ,the body cavity and both the bore ends can be blocked with each other even if both ends of the valve are under pressure at the same time, whereas the medium left in the body cavity may relieve through the relief valve.

SUNGO’s metal to metal sealed floating ball valve is of behind ball sealing structure, employing in general single direction tightness. The flow direction is indicated on the valve body. If specially required by customers, SUNGO’s patent of bi-direction sealing design may be selected.