QUAM CCH SERIES

QUAM CCH SERIES

Description

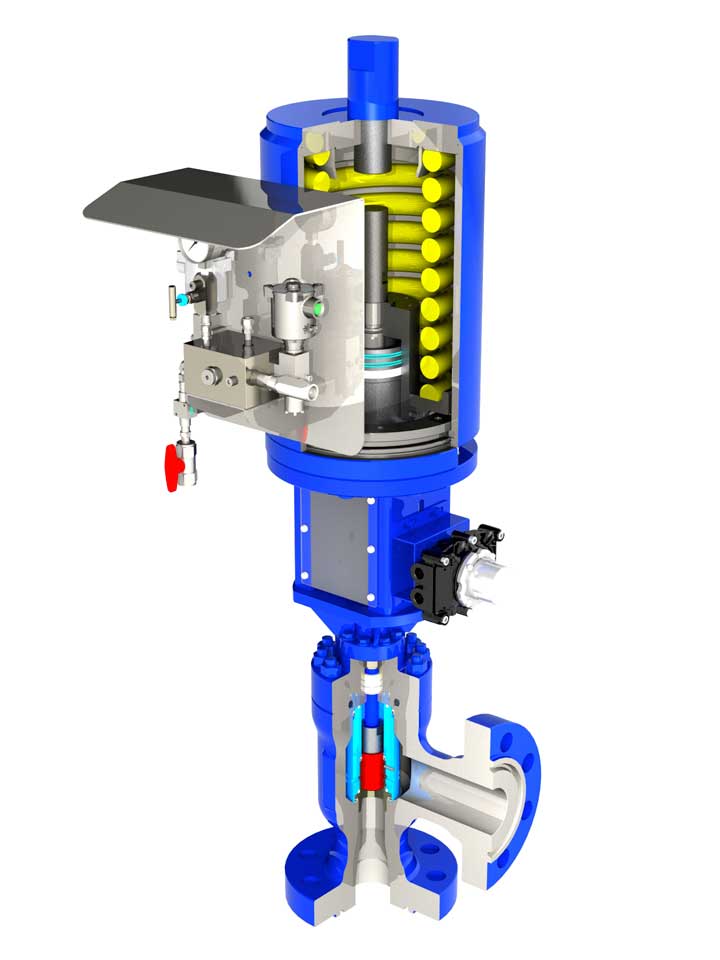

The QUAM CCH Series is a (internal) Plug & Cage Choke Valve complete with Single Acting Hydraulic Actuator

General Application

CCH is the Choke Valve suitable for installation on Christmas Trees, Choke & Kill or Production/Water injection Manifolds with High pressure Drop applications as well as suitable for Severe Service applications.

Certifications

- API-6A (Up to PSL-4)

- PED 2014-68-EU

- ATEX 2014-34-EU

- MACHINERY DIRECTIVE 2006/42/EC

QUAM serie: CCH Category: Plug & Cage Valve Tags: Actuated, Plug & Cage, Hydraulic.

- Key Features

- Benefits

- Technical Specification

- Trim Design – Ported Cage with Internal Plug trim design is available with Equal % or Linear characteristic. The flow passing across the cage impinges on itself and so turbulence and throttling wear are dissipated in the centre of the valve and not on valve outlet. The valve is provided with spacer.

- Erosion Resistant Trim – Valve Trim can be supplied in Hardened Stainless Steel or Solid Tungsten Carbide to provide the best wearing resistance.

- Metal to Metal Sealing – Without soft parts it is improved sealing performance with any process fluid.

- Position Indicator – AISI 316 SS Engraved Position Indicator available in Bean Size (1/64″) scale

- Locking Device – Stem Locking device provides safe valve positioning and holding the set point.

- No Threads in Valve Body – Trim Components are not Screwed in the Valve Body in order to facilitate disassembly.

- Proprietary Stem Packing Design – QUAM experience have been put in a special Stem Packing design for Smooth Operation, long life service and low emissions.

- Actuator Characteristics – Water (or other Fluid) pressure is applied only to one side of the piston. In case of emergency the actuator goes in fail open or close position.

- Exceed PR-2 Requirements – CCH Series Choke valves performance exceed API-6A PR-2 requirements.

- Exceptional Flow Control – Valve Trim is designed to perform an accurate Flow Control.

- Customized End to End Dimensions – The possibility to customize end to end dimensions allow the users an easy repalcement without pipeworks.

- Heavy Duty Construction – Valve is specially designed to improve reliability, Italian origin of Forging materials is the guarantee of Valve quality.

- Easy & Safe Maintenance – Special considerations in design are made to permit a safe disassembly of the pressure containing components.

- No Special Tools – CCH valves disassembly can be executed without any Special Tool, only Standard Wrenches are requested.

- 100% ITALIAN MANUFACTURING – QUAM Valves are Engineered and Manufactured entirely in Italy.

| Valve Action | Clockwise to Reduce Flow |

| Operated | QUAM Hydraulic Actuator |

| Valve Size Range | API-6A From 1 13/16″ through 11″ ANSI From 2″ through 12″ |

| Valve Pressure Ratings | API-6A From 2.000 through 20.000 PSI ANSI From 150 through 2500 lbs |

| Valve Connections | Flanged, Studded, Buttweld, Hub or Customized Connections, Hummer union |

| Operating Media | Oil, Natural Gas, Water and any combination of them |

| Operating Temperature | -60° C to +250° C |

| Shut-off Class | ANSI/FCI Class IV as standard Class V & VI available on request |