Our company, Sungo Valves Group Co.,Ltd. was founded in 1980 and is headquartered in Wenzhou, China. We specialize in Engineered Valves with over 40 years of experience and a team of highly skilled professionals, we have become a leading company in the Engineered Valves in Asia.

Our main products & services include Ball valve, Gate Globe Check valve, Butterfly Valve, Plug valve, Electric Actuator, Pneumatic Actuator and Gearbox, which are widely used in Gas& Oil, Power Generation, Chemical, Refining, Marine and Pipeline Transmission Industries Etc. We have established long-term partnerships with many well-known companies both domestically and internationally, and have received high praise for our quality products and excellent customer service.

At SUNGO, we are committed to providing our customers with the best possible products and services. We have a strict quality control system in place to ensure that our products meet the highest standards. We also have a professional and dedicated customer service team to provide timely and effective support to our customers.

In addition, we are a socially responsible company and strive to make a positive impact on the communities in which we operate. We have implemented environmentally friendly practices in our operations and have supported various charitable causes.

We look forward to working with you and providing you with the best products and services.

Advanced Manufacturing

The latest computer technology are also widely applied in SUNGO for valve manufacturing, this includes a large number of numeric control machines (Machining center, CNC horizontal and vertical lathe, CNC drilling machine) and ERR management system which significantly improve our machining quality and process control. SUNGO also employ a number of conventional lathe with capacity up to machine 52″gate valve. SUNGO manufacturing philosophy is to ensure stable quality and just in time delivery.

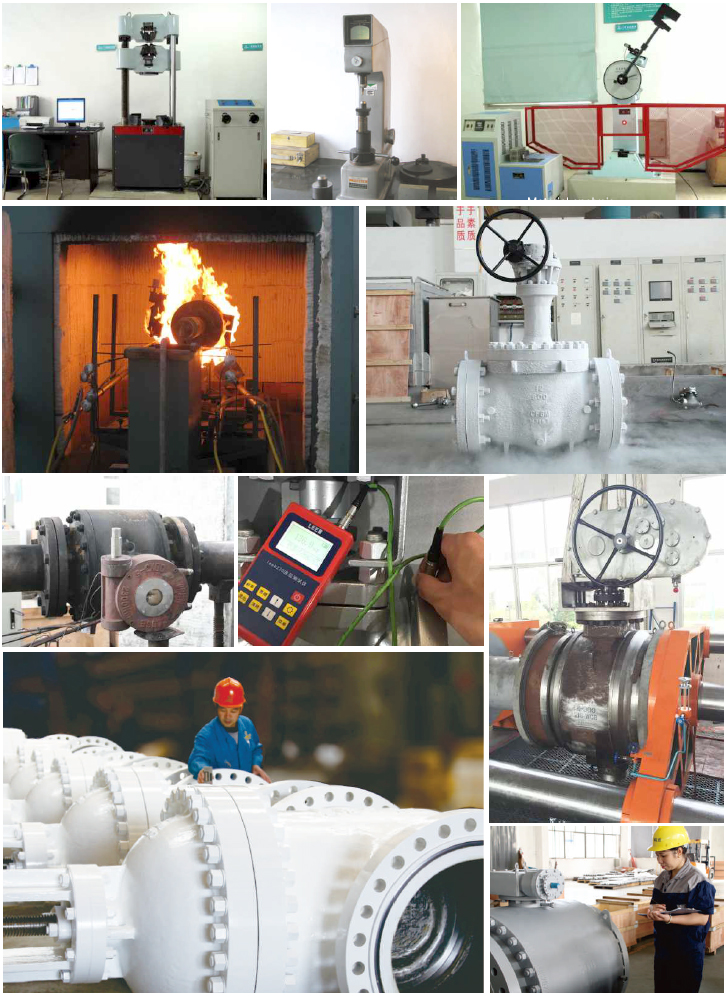

Complete & Efficient Quality Control System

SUNGO developed an extensive and advanced inspection and test facilities to control the quality from rough castings or forgings to final products. These facilities enable US to do Y Radial test. Radio graphic test, Ultra-sonic test, dye penetration test, Magnetic test, Positive Material Identifier (PM I) 1 Impact test, Tensile test, Hardness test, Fire safe test, Cryogenic test, Vacuum test, Low fugitive emission test, High pressure gas test, High temperature test and Hydro-Static test.

PRODUCTS

✪ BALL VALVES

- Floating Ball Valve

- Trunnion Ball Valve

- Metal To Metal Sealed Ball Valve

- Metal To Metal Sealed Floating Ball Valve

- Metal To Metal Sealed Trunnion Ball Valve

- One Piece Body Ball Valve

- Three Way Ball Valve

- Female Threaded Ball Valve

- Top Entry Ball Valve

- Full Welded Ball Valve

- Operation Torque Of Ball Valve

- Flow Coefficient Cv