Technical Features

TechnicalFeatures

Below are described some of the most important features

applied on OMS Saleri valves

|

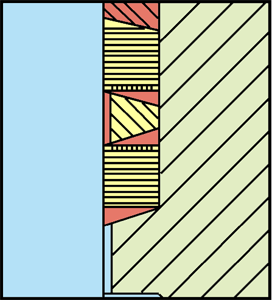

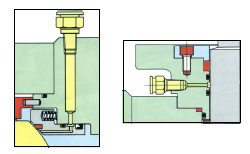

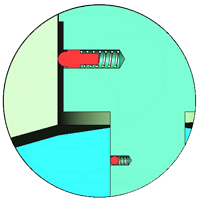

“Fire safe” execution OMS Saleri ball valves are “fire-safe” certified in accordance with BS 6755/API 607. In case thermoplastics or elastomerics seats are decomposed due to very high temperatures (in case of fire) the edge of the seat retainer comes into metal-tometal contact (by means of special springs) with the ball to shut-off the fluid and minimize internal fluid leakage through ball seats. |

|

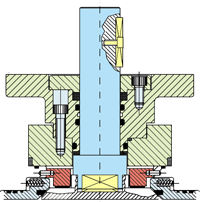

Blow out proof stem

|

|

Low operating torque Despite very large body size, OMS Saleri trunnion mounted ball valves are designed with utmost care for operational handling case. Low friction stem bearing materials and load on bearing are employed to reduce valve operation torque without lubricants and prevents stem galling. |

|

Packing An updated design is applied to the packing, given by peculiar shapes of the stuffing box, gland nut and rings of the packing. Furthermore, the last ones are composed by flat springs, PTFE rings and tilted metallic rings or graphite packing. All the above mentioned items co-operate to ensure a perfect tightness and an automatic compensation of the operational wear of the packing. |

|

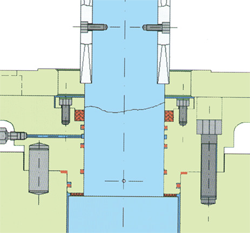

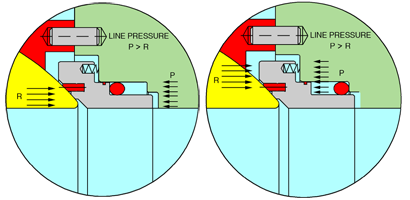

Double block and bleed Preloaded seats provide a double block & bleed function when a drain plug or a bleed valve is mounted to the bottom of the value body. This device protects against fluid contamination and verify the perfect tightning of seats without dismantling valves from line. |

|

Emergency seal In the event of any leakage from the seat or stem sealing area, a sealant supply mechanism is provided for size 6” and larger. For lower sizes it may be provided as an option. |

|

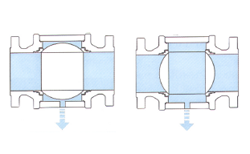

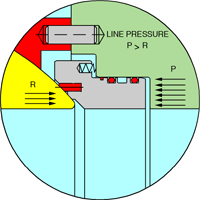

Piston action seat Two indipendent seats perfectly fitted into metallic seat ring preloaded with special springs assure a constant contact with ball sealing also at low differential pressures. |

|

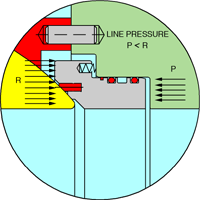

Cavity relief seat Two indipendent seats perfectly fitted into metallic seat rings assure the cavity relief in case of pressure increase in the body cavity above the given limits. The pressure itself is automatically released by the pressure acting on the seat rings. |

|

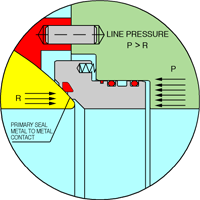

Delta ring seat Pipeline valves in gas service have special design with primary metal to metal seat and secondary seal by means an elastomeric delta ring wich assure the bubble tight sealing. |

|

Double piston effect seat Double piston effect seat is available upon request. The pressure in the body cavity increases the force on the seats against the ball in order to have higher reliability, even in case of failure of one of the seats. |

|

Antistatic device All OMS Saleri valves are fitted with anti-static devices that guarantee the electrical continuity between all component of the valves. |